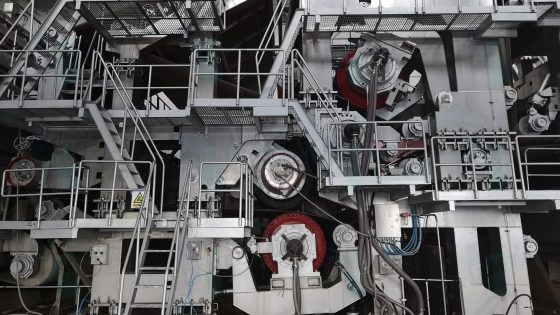

Paper making machines have an extra smoothing process called a calendar .Calendar consists of several rollers arranged vertically one upon the other, By running the almost dry paper web between the rollers under high pressure, the paper is compacted and smooth. The pressure applied to the web by the rollers determines the finish of the paper.

The primary purposes of the calender are can be summarized below.

Increase the quality of the final product.

Make the paper surface extra smooth and glossy

Gives it a more uniform thickness to the final product.

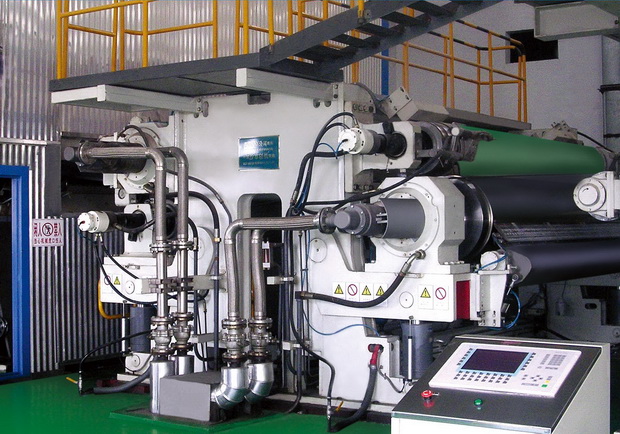

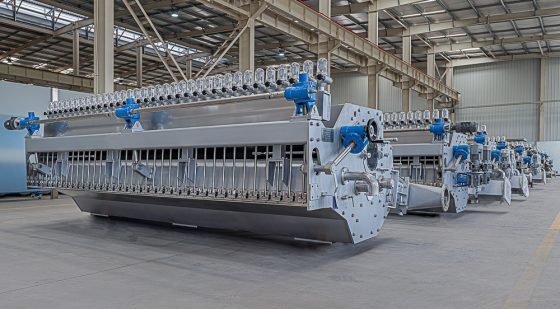

Calender Machine for Paper & Board Production

Unser calender machine is engineered to significantly improve the surface quality, Glätte, and gloss of paper and paperboard. Widely used in printing paper, beschichtetes Papier, kraft paper, Verpackungskarton, and specialty grades, the calender ensures excellent sheet finishing through precise pressure and temperature control.

Designed for high-speed, stabiler Betrieb, our calenders are available in soft-nip, hard-nip, multi-nip, and online/offline configurations, providing optimal flexibility for different production requirements.

Hauptmerkmale

- Superior Surface Finishing

Enhances sheet smoothness, gloss, and printability through uniform nip pressure and optimized nip geometry. - Consistent Paper Thickness

Advanced deflection-controlled rolls ensure uniform caliper across the entire web width. - Customizable Configuration

Available in soft-nip, hard-nip, multi-nip, and variable-crown roll designs to suit different paper types and finishing standards. - Energy-Efficient Heating System

Precise temperature control of the heated rolls ensures stable coating penetration and surface refinement. - High-Speed and Stable Operation

Robust frame, advanced drive system, and automatic tension control deliver reliable performance at high production speeds. - Integrated Automation & Control

Optional PLC/DCS control, automatic loading system, and real-time caliper monitoring improve productivity and reduce downtime.

Applications

- Coated paper (C1S/C2S)

- Art paper and high-grade printing paper

- Duplex board, ivory board, and white cardboard

- Kraft paper and packaging grades

- Specialty papers requiring precise surface finishing

Why Choose Our Calender Machine?

- Over 40 years of experience in paper machinery manufacturing

- Proven performance in global installations across Asia, Europe, Africa, and South America

- Custom solutions based on GSM range, speed, coating structure, and customer production goals

- Full lifecycle support: design → manufacturing → installation → commissioning → after-sales service

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken