The drying section serves two critical functions in the paper production process.

1.Removal of water from the sheet.

2.Achieve final desired MD & CD sheet moisture profiles while minimizing energy requirements.

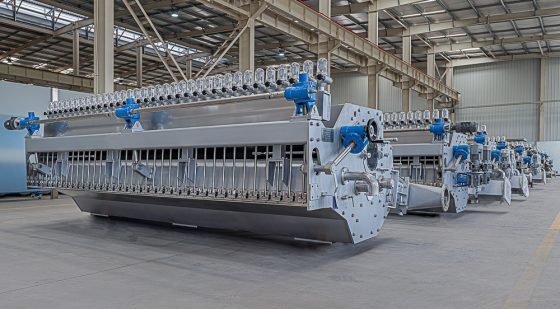

Trocknerzylinder is designed for high working pressure, its medium to heat is vapor. Its primary material is graded cast iron and alloy, and is composed by cylinder body and end closure. The dryer cylinder comes with a surface ground finish and are dynamically balanced. The dryer cylinder will have a great impact on the final moisture content of the paper and will also consist of the greatest energy usage in the paper making process.

Drying Section for Paper Machine

High-Efficiency Dryer Cylinders | Optimized Heat Transfer | Stable Web Drying

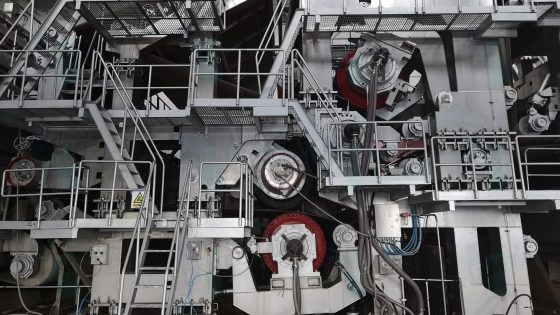

Unser Drying Section is engineered to deliver fast, stable, and energy-efficient moisture removal for all grades of paper and paperboard. Equipped with high-precision steam-heated dryer cylinders, optimized hood designs, and advanced moisture and tension control systems, the drying section ensures excellent drying uniformity and superior paper quality at high production speeds.

Designed for kraft paper, Gewebe, Duplex-Platine, white cardboard, and specialty grades, our drying section helps customers achieve higher operating speed, lower energy consumption, and improved sheet properties.

Hauptmerkmale & Advantages

- High-Efficiency Dryer Cylinders

Precision-machined cast-iron or steel dryer cylinders ensure uniform heat transfer and stable drying performance. - Optimized Steam & Condensate System

Advanced siphon and condensate removal systems maximize heat utilization and reduce steam consumption. - Stable Web Run & Tension Control

Well-designed guide rolls, stretch rolls, and felt runs ensure smooth sheet handling and reduce breaks. - Customizable Dryer Groups

Single-tier, double-tier, or combined drying configurations available according to paper grade and machine speed. - High-Quality Hood & Ventilation

Efficient hot-air ventilation improves drying efficiency while reducing energy usage. - Safety & Maintenance Friendly

Ergonomic layout with easy access for cleaning, felt change, and routine maintenance.

Applications

- Kraft paper & testliner

- Coated duplex board (C1S / C2S)

- White cardboard & ivory board

- Tissue and towel paper

- Specialty papers requiring controlled moisture profile

Why Choose Our Drying Section?

We are a leading manufacturer of paper machinery, providing robust and reliable drying solutions with long service life. Our designs focus on energy efficiency, stabiler Betrieb, and precise control, helping paper mills reduce costs and improve production output.

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken