The Size Press is used for applying starches, pigments, or chemicals to the surface of the product. The chemicals applied can be used to strengthen the product or to improve the printing quality of the product or even to improve the softness of the product.

Features:

Improve strength, surface smoothness in writing/printing/Media/Kraft/board

Add pigments to the surface of the web.

Better printability in printing paper/Kraft/Board

Improves bursting strength in Kraft papers

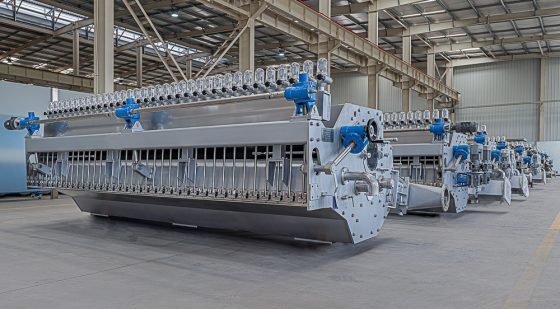

Size Press for Paper Machine (Surface Sizing System)

Enhance paper strength, surface quality, and printing performance with our high-efficiency Formatpresse, designed for modern paper and paperboard production lines. As a leading manufacturer of paper machinery, we offer advanced surface sizing solutions that ensure uniform starch application, improved sheet strength, and excellent runnability at high speeds.

Product Overview

Unser Formatpresse—available in both pond type Und film transfer type size press configurations—is engineered to apply starch, synthetic sizing agents, and functional chemicals onto the paper sheet. The system upgrades surface strength, reduces dusting and linting, improves ink holdout, and enhances print quality.

It is suitable for kraft paper, linerboard, Duplex-Platine, Schreiben & printing paper, and specialty coated grades.

Hauptmerkmale

- Uniform Surface Sizing: Advanced metering system ensures even starch penetration and stable coating weight across the entire web.

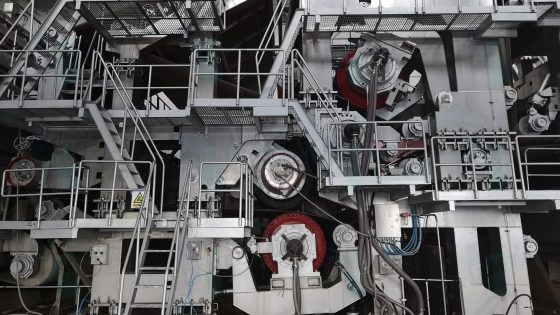

- High-Speed Operation: Robust frame and precision rolls support stable running at high production speeds.

- Improved Paper Strength: Significantly increases surface strength, internal bonding, stiffness, and water resistance.

- Energy-Efficient Design: Optimized drying integration reduces energy consumption after sizing.

- Durable Construction: High-quality stainless steel components, precision rolls, and reliable hydraulic systems ensure long service life.

- Flexible Configuration: Available as pond size press or film size press, depending on customer requirements and paper grade.

Technical Advantages

- Compatible with medium to high-speed Papiermaschinen

- Precise nip pressure control for stable sizing performance

- Easy integration with existing paper machine layout

- Optional recirculation system, starch preparation unit, Und automation control

Applications

- Kraft paper & linerboard

- Writing and printing paper

- Duplex board / coated board

- Food packaging paper

- Specialty papers requiring enhanced surface properties

Why Choose Our Size Press?

With years of experience in paper machine engineering and R&D, we deliver fully customized surface sizing systems that improve production efficiency, Ausfallzeiten reduzieren, and enhance product quality. Our machines are widely exported and recognized by customers worldwide for their performance and durability.

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken