Many papermaking machines are based on the principles of the Fourdrinier-Papiermaschine, which uses a specially woven plastic fabric mesh conveyor belt in the forming section, where a slurry of fibre (usually wood or other vegetable fibres) is drained to create a continuous paper web. After the forming section the wet web passes through a press section to squeeze out excess water, then the pressed web passes through a heated drying section.

Fourdrinier-Papiermaschine have four distinct operational sections:

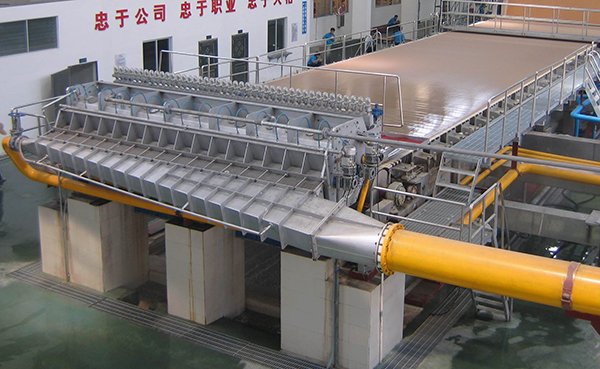

Formungsabschnitt, commonly called the wet end, is where the slurry of fibres filters out fluid a continuous fabric loop to form a wet web of fibre.

Pressebereich where the wet fibre web passes between large rolls loaded under high pressure to squeeze out as much water as possible.

Trockenbereich, where the pressed sheet passes partly around, in a serpentine manner, a series of steam heated drying cylinders. Drying removes the water content down to a level of about 6%, where it will remain at typical indoor atmospheric conditions.

Calender section where the dried paper is smoothened under high loading and pressure. Only one nip is necessary in order to hold the sheet, which shrinks through the drying section and is held in tension between the press section (or breaker stack if used) and the calender. Extra nips give more smoothing but at some expense to paper strength.

Unser Fourdrinier paper machine is a high-efficiency paper making machine designed for the continuous production of high-quality cultural paper, Verpackungspapier, kraft paper, fluting paper, and specialty grades. With advanced forming, drücken, Trocknen, and finishing technologies, the machine ensures excellent sheet formation, uniform fiber distribution, and stable moisture profiles across the entire web.

Engineered for modern paper mills, the Fourdrinier paper machine delivers high speed, geringer Energieverbrauch, and outstanding operational reliability—making it one of the most widely used paper production lines in the global paper industry.

Hauptmerkmale

- High-Quality Sheet Formation: The Fourdrinier forming section provides superior fiber dispersion, excellent formation, and consistent paper quality.

- Efficient Press Section: Optimized press configuration (single press, double press, or shoe press) to improve dryness, enhance strength, and reduce steam consumption.

- Advanced Drying System: Multi-cylinder drying section with steam and condensate system for fast, uniform moisture removal and reduced energy cost.

- Stable Operation at High Speed: Robust frame design, precise tension control, and modern lubrication systems ensure smooth, continuous production.

- Customizable Configuration: Machine width, design speed, paper grade, automation level, and energy-saving options can be customized for each paper mill.

- Easy Maintenance: Modular structure with accessible components and intelligent control systems for simplified operation and reduced downtime.

Applications

- Printing and writing paper

- Copy paper / tissue base paper

- Kraft paper / fluting paper / testliner

- Duplex board top layer

- Specialty industrial papers

Why Choose Our Fourdrinier Paper Machine?

- Over 40 years of experience in paper mill equipment manufacturing

- Complete solution from stock preparation to finished paper

- International-brand components (SKF, Siemens, ABB, Schneider) available

- Strong engineering team for Installation, Inbetriebnahme, and training

- Global service network and proven performance in many countries

Technische Daten:

Rohstoff: Recyclingpapier,Virgin pulp

Ausgabepapier: Kraft paper/Corrugated paper/Writing paper/Copy paper,usw

Gewicht: 40-500GSM

Draht: bis zu 5 wires(5 layers)

Nettopapierbreite: up to 6600mm

Kapazität: up tp 1000T/D

Arbeitsgeschwindigkeit: up tp 1000m/min

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken