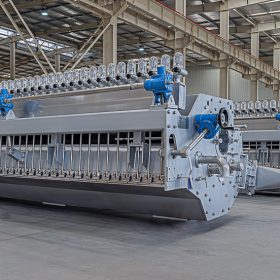

We supply quality Head Box such as open type Head Box, air-cushioned Head Box, hydraulic Head Box, which is widely demanded by our customers. The Head box serves three important functions in the paper production process. If the Head box does not perform acceptably in any of these three functions, the quality of the paper produced will be greatly diminished.

1. Spread the stock evenly along the width of the paper machine.

2. Accelerate the stock up to the machine operating speed.

3. Suspend the pulp fibers throughout the outgoing slurry.

Headbox for Paper Machine — High-Precision Flow Distribution & Superior Formation

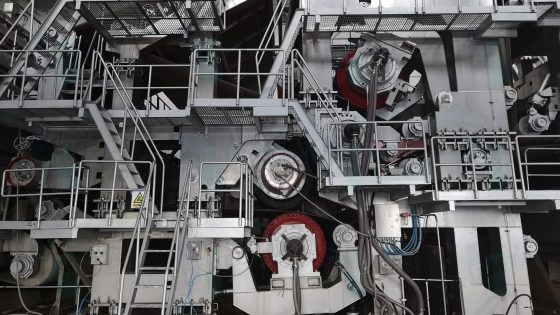

Unser Stoffauflauf is a core component of the paper machine, engineered to deliver uniform pulp distribution across the entire wire width and ensure optimal sheet formation. Designed for high-speed paper and board production, the headbox provides precise control of stock flow, fiber dispersion, and turbulence—directly influencing paper quality, strength, and formation.

Whether for tissue, Schreiben & printing paper, kraft paper, Duplex-Platine, or specialty grades, our headbox systems ensure consistent performance, stabiler Betrieb, and excellent sheet properties.

Hauptmerkmale & Advantages

✔ Uniform Fiber Distribution

Advanced turbulence generator and flow rectification system ensure even fiber dispersion, reducing streaks, flocs, and formation defects.

✔ Hydraulic or Air-Cushion Design

Available in hydraulic headbox, air-cushion headbox, Und multi-layer headbox configurations to meet different production needs.

✔ Accurate Dilution Control System (Optional)

Modern dilution water control allows precise basis-weight profiling across the paper width, improving MD/CD uniformity and reducing raw material cost.

✔ Stable Sheet Formation

High turbulence intensity and stable jet-to-wire ratio enhance sheet formation, reduce fiber orientation issues, and improve paper strength.

✔ High-Quality Materials

All wet-contact components are made from SS304 or SS316L, ensuring corrosion resistance, lange lebensdauer, and low maintenance requirements.

✔ Customizable for Any Paper Grade

- Tissue

- Kraft & testliner

- Duplex board & whiteboard

- Coated paper

- High-grade cultural paper

- Specialty paper

Technical Highlights

- Machine width: 1,500–8,000 mm (customizable)

- Designed speed: 200–1,200 m/min

- Flow control: electropneumatic actuators or manual slice control

- CD profile accuracy: ±1–2% with dilution system

- Turbulence generation tailored to pulp grade and speed

Why Choose Our Headbox?

- Over 40 years of experience in pulp & paper machinery manufacturing

- Advanced CNC machining ensures micron-level accuracy

- Proven performance in mills across Asia, Middle East, Europe, Africa

- Fully customizable to match your mill’s production goals and budget

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken