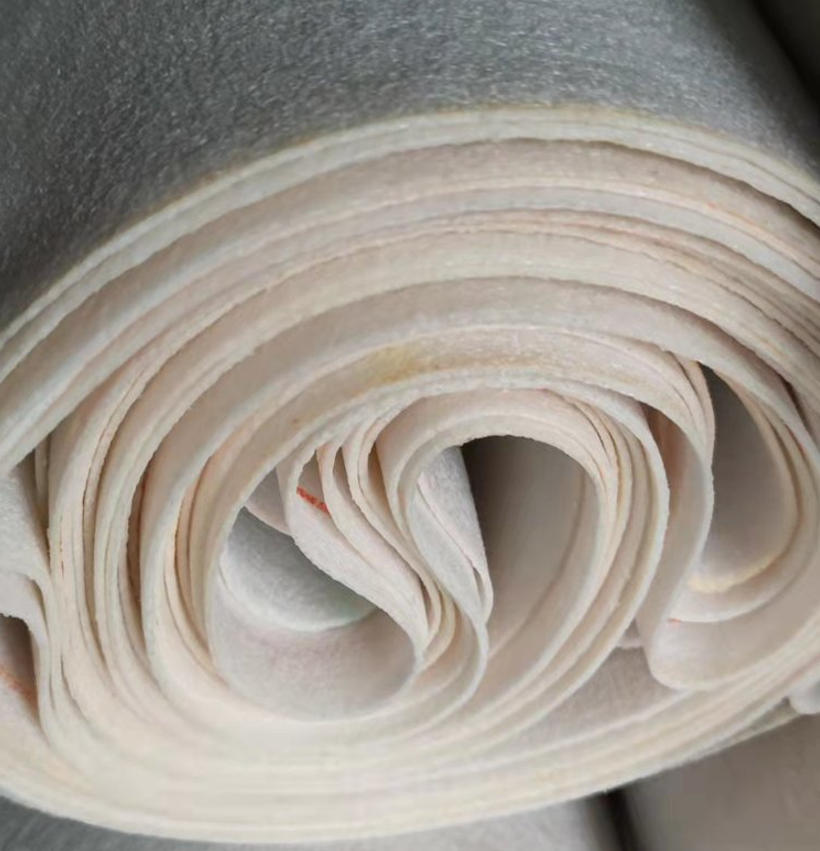

Paper Making Felt – High-Performance Press Felt for Paper Machines

Unser paper making felts are engineered for optimal water removal, sheet support, and runnability across all types of paper and board machines. Made from high-grade synthetic fibers and advanced needling technology, our felts ensure excellent dewatering efficiency, dimensional stability, and long service life in demanding press-section environments.

We supply a full range of press felts for different positions, including pick-up felts, forming press felts, bottom/top felts, jumbo press felts, and shoe press felts. Each felt is custom-designed according to machine speed, paper grade, and press configuration to guarantee maximum performance and energy savings.

Hauptmerkmale

- High water absorption and superior dewatering capability

- Excellent tensile strength and dimensional stability

- Smooth surface for improved sheet formation and fewer paper defects

- Long service life with reliable performance under high pressure

- Low steam consumption and improved drying efficiency

- Available in single-layer, double-layer, and laminated structures

Applications

Our paper making felts are suitable for:

- Kraft paper machines

- Testliner and fluting paper machines

- Cultural paper machines

- Tissue machines

- Specialty paper production

Why Choose Our Felts?

We offer customized design, fast delivery, and consistent high quality backed by modern production technology and strict quality control. Our felts help improve your machine performance, Ausfallzeiten reduzieren, and lower overall operating costs.

Q1: Sind Sie ein Hersteller oder ein Handelsunternehmen??

A: Wir sind ein professioneller Hersteller von Zellstoff & Papierfabrikmaschinen mit vollständigem Design, Produktion, Installation, und After-Sales-Funktionen.

Q2: Welche Arten von Papiermaschinen liefern Sie??

A: Wir bieten komplette Produktionslinien und Schlüsselausrüstung für Kraftpapier, Seidenpapier, Kulturpapier, Duplex-Platine, Spezialpapier, und mehr.

Q3: Wie lange ist Ihre Lieferzeit??

A: Normalerweise 60–120 Tage, abhängig vom Maschinentyp, Produktionskapazität, und Anpassungsanforderungen.

Q4: Wie lange ist Ihre Garantiezeit??

A: Wir bieten eine 12-monatige Garantie nach Inbetriebnahme. Lebenslanger technischer Support ist verfügbar.

F5: Bieten Sie Installation und Schulung an??

A: Ja. Wir schicken professionelle Ingenieure zur Installation in die Mühle des Kunden, Inbetriebnahme, und Bedienerschulung.

F6: Wie verpacken Sie die Ausrüstung für den Versand??

A: Alle Teile sind in Export-Standard-Holzkisten verpackt, Stahlrahmen, oder feuchtigkeitsbeständige Verpackung, um einen sicheren Transport zu gewährleisten.

F7: Wie lautet Ihr Zahlungsziel??

A: Typischerweise 30% Vorauszahlung und 70% vor dem Versand, oder L/C auf Sicht. Andere Konditionen können ausgehandelt werden.

Wir sorgen für Sicherheit, Professional, und zuverlässige Verpackungslösungen, um sicherzustellen, dass die gesamte Ausrüstung Ihr Werk in einwandfreiem Zustand erreicht. Jede Komponente wird sicher in Standard-Exportholzkisten verpackt, Stahlrahmen, oder feuchtigkeitsbeständige Verpackung je nach Bedarf.

Unser Logistikteam sorgt für eine pünktliche Lieferung auf dem Seeweg, Land, oder Luft je nach Kundenwunsch. Wir arbeiten mit vertrauenswürdigen internationalen Spediteuren zusammen, um einen reibungslosen Versand zu gewährleisten, genaue Dokumentation, und pünktliche Ankunft.

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken