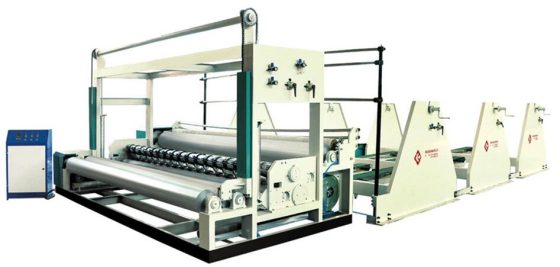

Duplex sheet cutter cut jumbo roll into paper sheet or paperboard ,it can cut kraft paper ,A4 paper ,photo paper ,Kopierpapier,newsprint,usw.

Function:

Duplex sheet cutter is heavy type paper cutter ,which can cut various paper roll into different paper sheet .it can cut various paper such as printing paper, Kopierpapier,kraft paper ,photo paper,paper board etc.

Feature:

1.Automatically control and adjust the finished paper sheet size

2.Easy to operate and maintain

3.Automatically protection system

4.Low noisy

5.Speed control

Duplex Sheet Cutter – High-Precision Paper & Board Cutting Machine

Unser Duplex-Blattschneider is a high-efficiency and high-precision cutting machine designed for duplex board, kraft board, grey board, beschichtetes Papier, and various packaging paper grades. It ensures smooth, accurate sheet cutting with stable operation, making it an ideal solution for paper mills, packaging plants, and paper converting industries.

Product Overview

The Duplex Sheet Cutter adopts advanced servo control and PLC automation to achieve precise length cutting, stable sheet delivery, and clean edges. With optimized mechanical structure and durable materials, the machine guarantees long-term performance and reliability even in continuous high-speed production.

Hauptmerkmale

- High Cutting Precision: Advanced servo system ensures ±0.5–1mm accuracy for consistent sheet size.

- Wide Application: Suitable for writing paper, Kopierpapier,Duplex-Platine, kraft paper, grey board, beschichtetes Papier, ivory board, and other paper grades from 30–1000 GSM.

- High-Speed Operation: Designed for smooth cutting at high speed while maintaining stability and uniform sheet quality.

- Robust Construction: Heavy-duty frame and premium components extend machine lifetime and reduce maintenance downtime.

- User-Friendly Operation: PLC touch-screen interface for easy length adjustment, job switching, and fault monitoring.

- Energy Efficient: Optimized transmission system reduces power consumption while maximizing productivity.

Technical Advantages

- Precise sheet length control with servo drive

- Vibration-free cutting structure

- High-strength blades for clean and smooth cutting edges

- Synchronous sheet delivery system

- Compatible with single-ply or multi-ply duplex board production lines

Applications

This duplex sheet cutter is widely used in:

- Duplex board production lines

- Packaging paper mills

- Printing and converting plants

- Paper sheeting and finishing workshops

Why Choose Us

With more than 40 years of experience in paper machinery manufacturing, we provide reliable equipment, professional installation, and comprehensive after-sales service. Our duplex sheet cutters are exported worldwide and are highly praised for stability, precision, and durability.

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken