Paper doesn’t generally sold by the jumbo, thus it must be scaled down. The slitter rewinder is used to process these jumbos made from paper making machine into manageable and sellable products, the width and tightness of rewinding meets the requirements of finished sheet rolls. In the process of rewinding, it can also remove the bad-quality paper sheets, adhesive end breakage.

The slitter rewinder is an off-machine operation and is not a part of the paper making process. Rather,it is the the start of the converting process. To sum things up, the winder accomplishes the following tasks: process parent reels into sellable products.

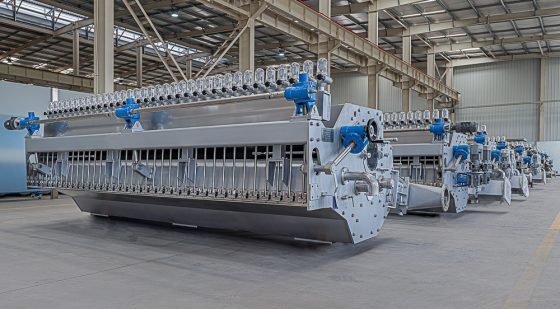

Slitter Rewinder Machine

High-Precision Slitting & Rewinding for Paper, Film, and Nonwoven Materials

Unser Slitter Rewinder Machine is engineered for high-speed, high-accuracy slitting and rewinding of a wide range of materials, including tissue paper, kraft paper, beschichtetes Papier, board, film, and nonwoven products. Designed for stable performance and easy operation, it delivers perfectly rewound rolls with precise slit edges—ideal for converting and finishing applications.

Product Overview

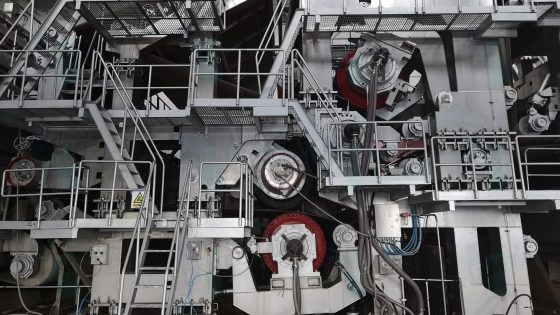

This advanced paper slitter rewinder features servo-controlled tension management, automatic web guiding, and high-precision rotary knives to ensure consistent product quality. Whether for large mother rolls or small finished rolls, the machine provides clean slitting, tight rewinding, and excellent roll formation. It is an ideal choice for paper mills, converting plants, packaging manufacturers, and tissue producers looking to enhance production efficiency.

Hauptmerkmale

- High-Speed Slitting Performance

Achieves stable slitting and rewinding at high speeds, maximizing productivity. - Precision Slit Accuracy

Equipped with adjustable circular knives or razor blades to ensure <0.1 mm slit tolerance. - Automatic Tension Control

Closed-loop tension system ensures perfect roll hardness and consistent quality across the entire web. - Versatile Material Compatibility

Suitable for tissue paper, printing paper, kraft paper, Duplex-Platine, beschichtetes Papier, film, foil, and nonwovens. - User-Friendly Operation

PLC + touch screen interface for easy setup, monitoring, and parameter adjustments. - Strong and Durable Design

Heavy-duty frame construction ensures long service life and stable operation.

Applications

- Paper converting

- Tissue roll production

- Packaging material processing

- Printing and lamination plants

- Specialty paper and film slitting

Why Choose Our Slitter Rewinder?

Mit 40 years of experience in paper machinery manufacturing, we provide customized slitter rewinder solutions tailored to your production requirements. Our machines are known for precision, reliability, and energy efficiency, helping clients reduce downtime and improve overall output quality.

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken

Hersteller von Papiermaschinen & Anbieter | Komplettlösungen für Papierfabriken