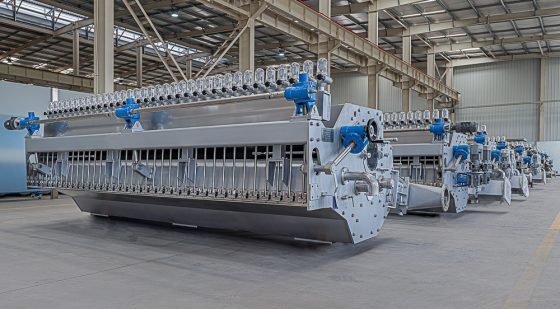

The task of the press section is to continue to remove water from the pulp fibers and to smooth the surface characteristics of the felt and wire sides ( top and bottom sides ) of the paper web running the length of the machine. Various types of press section can be made based on the requirement.

Press Section for Paper Machine

High-Efficiency Dewatering & Web Strengthening Solutions for Modern Paper Mills

Nuestro press section is engineered to deliver maximum dewatering efficiency, resistencia de la hoja mejorada, and stable paper web transfer for all types of paper and board machines. Designed with advanced press roll configurations and optimized loading systems, it ensures lower steam consumption, reduced energy cost, and enhanced paper quality.

The press section can be customized for tissue, papel kraft, fluting, testliner, tablero dúplex, papel cultural, specialty grades, and high-speed paper machines.

Características clave

- High Dewatering Capacity

Advanced press loading and felt design significantly increase dryness before the dryer section, reducing overall energy usage. - Multiple Press Configurations

Options include single press, double press, triple press, K -press,Four-roll three-nip press,shoe press, vacuum press, pick-up press, y combi-press systems tailored to your production needs. - Stable Web Transfer

Optimized press geometry and vacuum-assisted pickup ensure smooth sheet transfer with minimal paper breaks. - Resistencia del papel mejorada & Uniformity

Consistent nip pressure and controlled dewatering deliver better bulk, strength, smoothness, and formation. - Durable & Low-Maintenance Design

Componentes de acero inoxidable de alta calidad., anti-corrosion frames, and precision-manufactured press rolls ensure long service life. - Energy-Saving Operation

Higher inlet dryness reduces load on the dryer section, lowering steam consumption and operating cost.

Technical Options

- Press rolls: granite roll, stone roll, rubber-covered roll, vacuum press roll, suction pick-up roll, blind-drilled roll

- Shoe press: hydraulic loading, controllable crown, composite belt

- Felts: pick-up felt, press felt, transfer felt

- Automation: pneumatic loading, hydraulic loading, online pressure control

Aplicaciones

- máquina de papel kraft

- Duplex board machine

- Tissue paper machine

- Líneas de prueba / fluting machine

- Cultural paper machine

- Specialty paper production

Why Choose Our Press Section?

With decades of experience in paper machine manufacturing, we provide complete engineering support, customized design, installation guidance, and after-sales service to help you achieve higher production efficiency and superior paper quality.

Fabricante de máquinas de papel & Proveedor | Soluciones completas para fábricas de papel

Fabricante de máquinas de papel & Proveedor | Soluciones completas para fábricas de papel