抄紙機のセクション

Sections of a Paper Machine

A paper machine is typically divided into several major sections, each responsible for a specific part of the papermaking process. The main sections include:

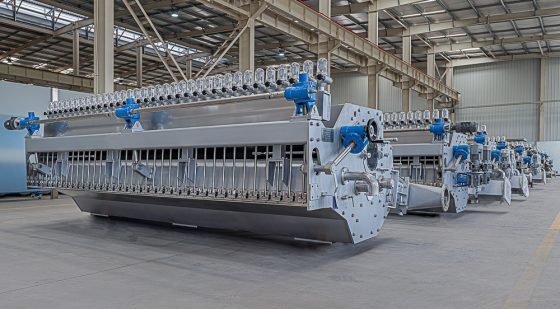

ヘッドボックス

The headbox delivers a uniform and well-dispersed slurry of fibers onto the forming section. It controls fiber distribution, consistency, and basis-weight profile across the machine width.

Forming Section (Wire Section)

In this section, the diluted pulp is drained on a moving wire or forming fabric. Water is removed by gravity, vacuum, and foils. This is where the paper sheet is first formed and its basic structure is established.

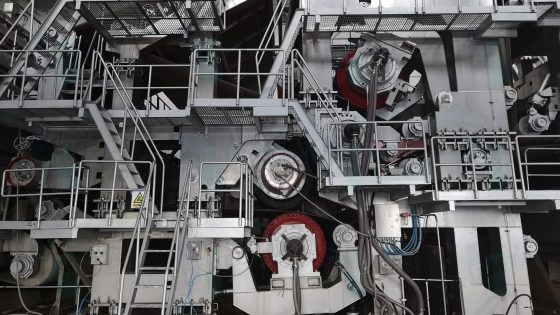

Press Section

The partially formed sheet passes through one or more press nips, where mechanical pressure removes additional water and increases sheet density and strength. Modern machines may include shoe presses or controlled-crown rolls for improved dewatering and surface quality.

Dryer Section

The sheet is dried using a series of steam-heated dryer cylinders. As the paper travels through multiple drying groups, moisture is evaporated until the desired dryness is achieved. This section has a major influence on paper quality and energy consumption.

Size Press / Film Press (Surface Treatment)

A size press or film press applies starch or other surface agents to improve paper strength, surface properties, and printability.

Coating Section (オプション)

For coated paper grades, one or more coating stations apply a controlled amount of coating color to improve whiteness, smoothness, and print surface.

Calender Section

The calender smooths and polishes the sheet by passing it through hard or soft nips. It improves gloss, thickness uniformity, and surface finish.

Reel Section (Pope Reel)

The finished paper sheet is wound into a large jumbo roll at the end of the machine. Tension and hardness are carefully controlled to ensure proper winding quality.

Winding Section (Rewinder)

The jumbo roll is rewound into smaller rolls with the required width and diameter according to customer specifications. Slitting knives are used to achieve precise width control.

抄紙機メーカー & サプライヤー | 完全な製紙工場ソリューション

抄紙機メーカー & サプライヤー | 完全な製紙工場ソリューション