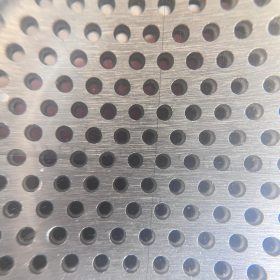

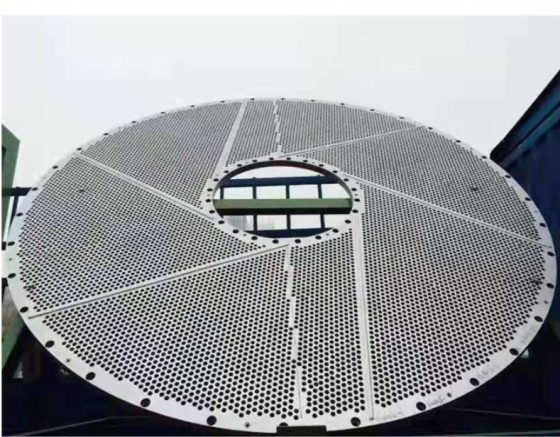

Perforated Plate for Pulp– High-Precision Stainless Steel Screen Plate

우리의 perforated plate (also known as screen plate for pulp screening &washing systems) is engineered for high-efficiency fiber separation and stable pulp screening performance in modern pulp & paper mills. Manufactured from premium stainless steel and processed with CNC drilling technology, our perforated plates deliver excellent wear resistance, smooth surface finish, and consistent hole accuracy.

Designed for applications in Andritz DD washer(drum displacer washer ),Valmet Twinroll press washer , our perforated plates ensure improved screening efficiency, reduced energy consumption, and longer service life.

주요 특징

- High-precision CNC-drilled perforations ensuring uniform hole geometry and stable screening performance.

- Premium stainless steel material (/SS316 / SMO254) for excellent corrosion and wear resistance.

- Smooth polished surface to minimize fiber blockage and improve throughput.

- Optimized open area increasing screening capacity and reducing power consumption.

- Custom hole diameters, including 1.2 mm, 1.4 mm, 1.8 mm, slotted holes, stepped holes, and profile holes.

- Long service life with high mechanical strength and anti-abrasion properties.

응용

- Andritz DD washer(drum displacer washer )

- Valmet Twinroll press washer

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션