Refiner Plates Manufacturer & 공급자

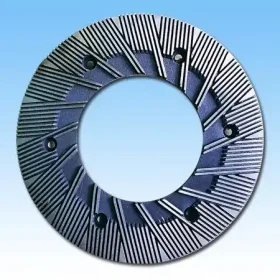

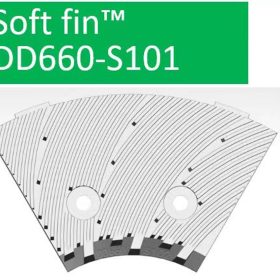

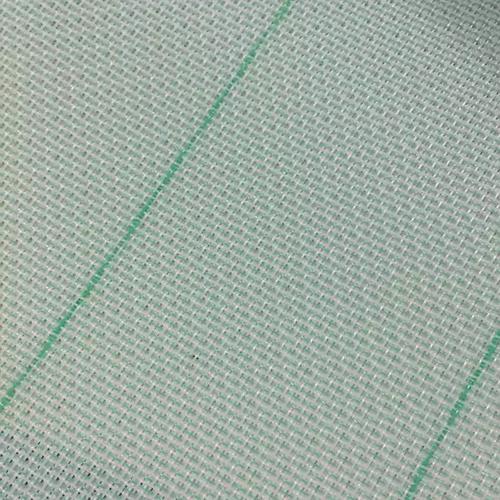

We manufacture and supply high-quality refiner plates for the pulp and paper industry, widely used in stock preparation systems for fiber refining and energy-efficient pulp processing.

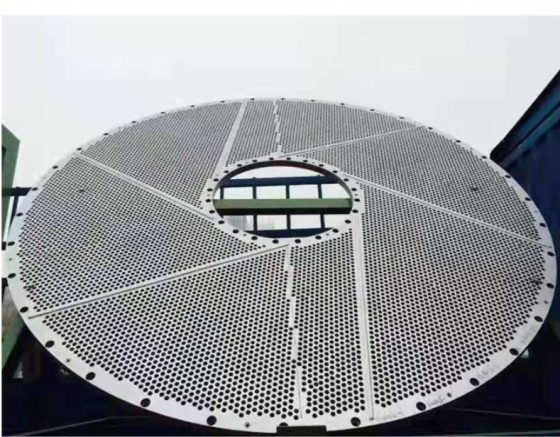

Our refiner plates are suitable for various single disc refiners, double disc refiners (DDR) and other refining equipment used in paper mills.

Product Features

-

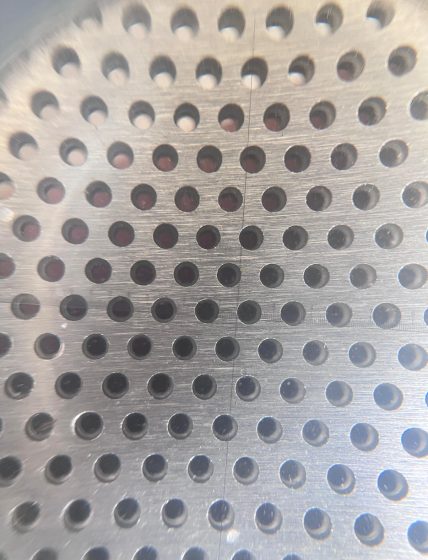

Precision-machined plate patterns for stable refining performance

-

Long service life with uniform wear

-

Available in different materials and hardness levels

-

Suitable for mechanical pulp and recycled fiber processing

-

OEM replacement and customized designs available

Application

-

펄프 & paper mills

-

Recycled fiber processing lines

-

Stock preparation systems

-

Mechanical and semi-chemical pulping

Custom Manufacturing

We can manufacture refiner plates according to customer drawings, samples, or OEM specifications, including plate diameter, bar pattern, segment design, and material selection.

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션