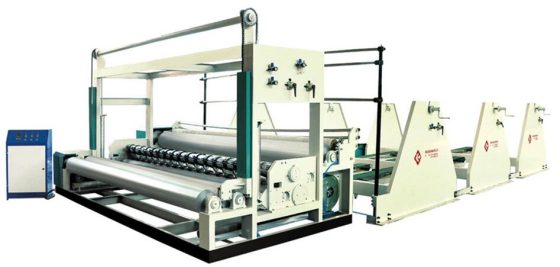

Full-automatic tissue paper rewinding/perforation/embossing machine

The full-automatic tissue paper rewinding/perforation/embossing machine is mainly used for rewinding the tissue jumbo roll into two-layer or three-layer toilet paper. It adopts computer programming control of PLC and pneumatic control system, setting perforating, rolling, embossing, automatic gluing, cutting, sealing in one machine, automatically running, simply operating. It can produce hollow -core and solid-core toilet roll. The embossing device is optional, and the embossing pattern can be customized.

Specification:

| Type | 1575 | 1880 | 2400 |

| Parent roll size(mm) | 800*1750 | 800*2100 | 800*2600 |

| Diameter of production(mm) | 80-150 | 80-150 | 80-150 |

| Diameter of paper core(mm) | 30-50 | 30-50 | 30-50 |

| Speed (m/나) | 150-250m/나 | ||

| Power | 3kw | 5.5kw | 7.5 |

| Dimension(mm) | 5600*2400*1500 | 5600*2700*1500 | 5600*3200*1500 |

High speed type:

| Type | 3200mm |

| Size of parent roll | Φ1100×3000mm |

| Diameter of production | Φ60-Φ150mm |

| Parent roll stands | 3 |

| Core inner diameter | 76mm |

| Perforating unit | 1 |

| Embossing unit | 1 |

| Speed | 300m/나 |

| 용량 | 6-7 tons |

| Pneumatic parent roll loading | 예 |

| Rewinding for a given diameter function | 예 |

| Automatic cutting& gluing& formation of a tail | 예 |

| 제어 | Frequency convertor& PLC |

| Power | 11 kw |

| Contour dimension | 6000×4000×1500mm |

| Weight | 4.5 tons |

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션