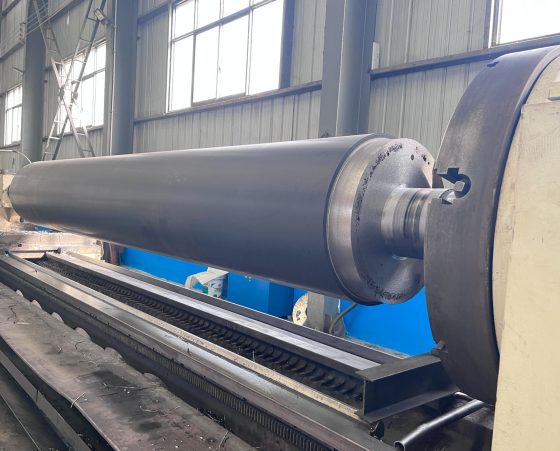

Suction / Vacuum Roll for Paper Machine – High-Efficiency Dewatering & Stable Operation

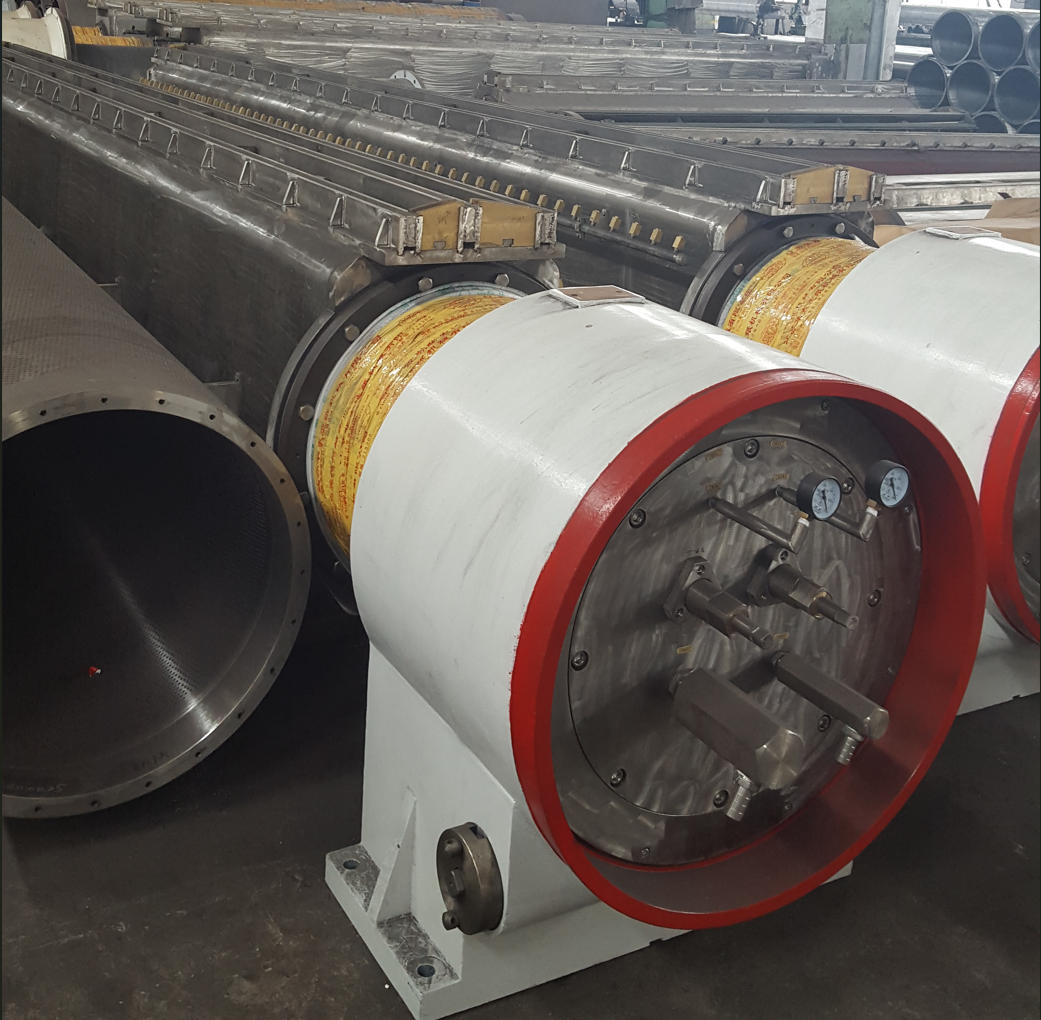

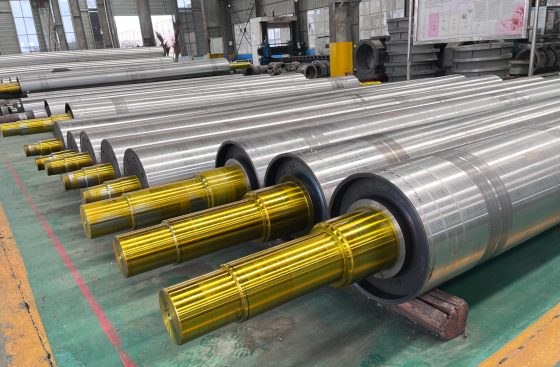

우리의 suction roll (also called vacuum roll) is engineered for efficient dewatering, stable sheet transfer, and reliable performance in paper and board machines. Manufactured with a high-strength stainless steel or composite shell, precision-drilled suction holes, and a balanced internal vacuum system, the roll ensures excellent runability and long service life under demanding operating conditions.

Designed for the press section and forming section—including suction press roll, vacuum pick-up roll, couch roll, vacuum transfer roll—our suction rolls help optimize water removal, improve paper formation, and reduce energy consumption.

주요 특징

- High-efficiency dewatering with optimized hole pattern and vacuum zone design

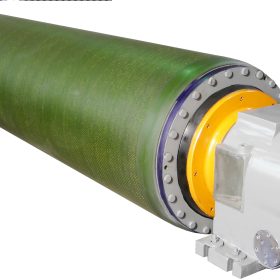

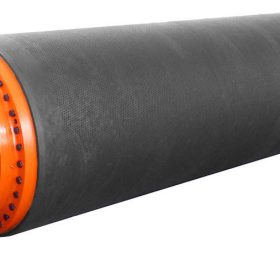

- Stainless steel or composite shell with precision machining for maximum durability

- Dynamic balancing up to G1.6 / G2.5 for smooth operation at high speeds

- Advanced ceramic or rubber cover options for superior wear resistance

- Custom-designed vacuum box with adjustable vacuum zones

- Heavy-duty bearing housing ensuring stable operation and long service life

- Optional internal oscillation system for uniform cover wear

- Suitable for high-speed paper machines across all grades

응용

- Vacuum pick-up roll for sheet transfer

- Suction press roll for improved press dewatering

- Couch roll in forming section

- Vacuum transfer roll for tissue, kraft, linerboard, and writing paper machines

Product Advantages

- Increased dryness after press section

- Reduced steam consumption in dryer section

- Improved sheet formation and paper quality

- Lower operating cost with long-lasting cover materials

- Custom design for width, diameter, vacuum zones, and drilling pattern

Why Choose Our Suction / Vacuum Roll?

With years of experience in papermaking machinery manufacturing, we produce suction rolls using CNC machining, heat treatment, advanced welding, and precise dynamic balancing. Every roll is tested under strict quality control standards to ensure reliable performance and minimal downtime in your production line.

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션

제지 기계 제조업체 & 공급자 | 완벽한 제지 공장 솔루션