Pneumatic Corrector for Paper Machine – Automatic Web Guiding & Alignment System

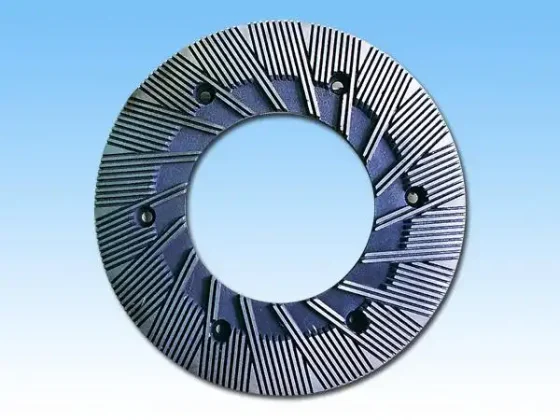

Our Pneumatic Corrector is a high-precision web guiding system designed to ensure stable sheet alignment and accurate edge position control on paper machines. Using a sensitive pneumatic sensor and fast-response actuator, the system continuously corrects web deviation to guarantee smooth operation and high-quality paper formation.

This equipment is widely used in the forming section, press section, and dryer section of various paper machines, helping mills reduce sheet breaks, improve runability, and increase production efficiency.

Key Features

- High-precision pneumatic sensing for real-time detection of web deviation.

- Fast-response pneumatic actuator ensures accurate and stable alignment.

- Automatic edge position control (EPC) prevents sheet drifting, wrinkling, and tracking issues.

- Strong structural design for stable operation under high speed and heavy load.

- Simple installation & low maintenance, suitable for all types of paper machines.

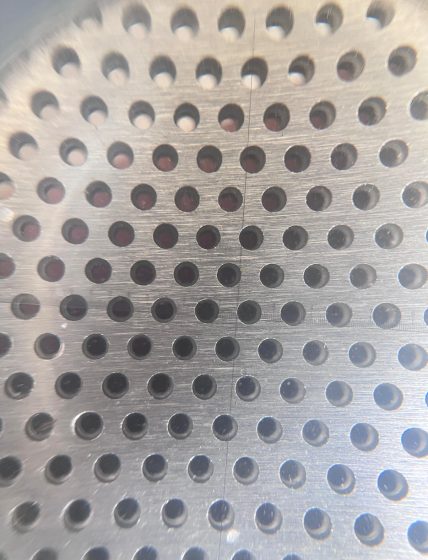

- Corrosion-resistant materials, ideal for humid papermaking environments.

Applications

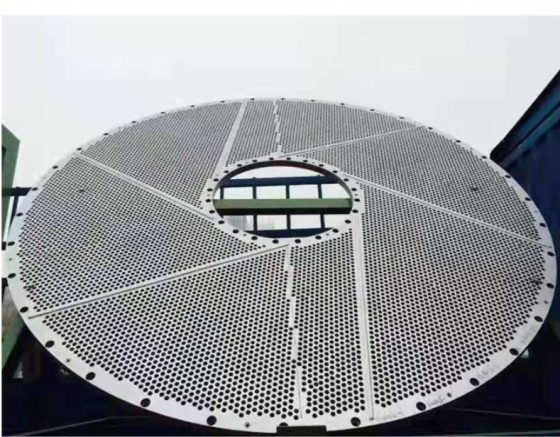

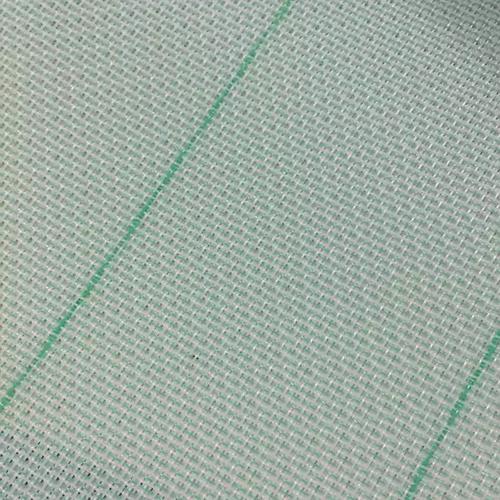

- Forming section wire guiding

- Felt guiding system in press section

- Dryer screen tracking control

- Rewinders, winders, and finishing equipment

- Any production line requiring precise web alignment

Why Choose Our Pneumatic Corrector?

With years of experience in papermaking machinery manufacturing, we provide reliable, accurate, and durable pneumatic correction systems that significantly reduce downtime and improve machine efficiency. Each unit is tested under simulated operating conditions to guarantee stable long-term performance.

Paper Machine Manufacturer & Supplier | Complete Paper Mill Solutions

Paper Machine Manufacturer & Supplier | Complete Paper Mill Solutions