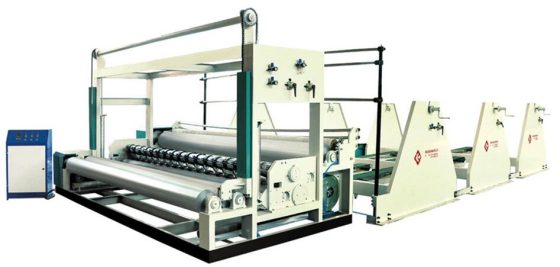

A4 Paper Cutting & wrapping machine

- Product Details

- FAQs

- Packing & Delivery

Q1: Are you a manufacturer or a trading company?

A: We are a professional manufacturer of pulp & paper mill machinery with full design, production, installation, and after-sales capabilities.

Q2: What types of paper machines do you supply?

A: We provide complete production lines and key equipment for kraft paper, tissue paper, cultural paper, duplex board, speciality paper, and more.

Q3: How long is your delivery time?

A: Normally 60–120 days depending on the machine type, production capacity, and customization requirements.

Q4: What is your warranty period?

A: We offer a 12-month warranty after commissioning. Lifetime technical support is available.

Q5: Do you provide installation and training?

A: Yes. We send professional engineers to the customer’s mill for installation, commissioning, and operator training.

Q6: How do you pack the equipment for shipment?

A: All parts are packed with export-standard wooden cases, steel frames, or moisture-proof wrapping to ensure safe transportation.

Q7: What is your payment term?

A: Typically 30% advance payment and 70% before shipment, or L/C at sight. Other terms can be negotiated.

We provide safe, professional, and reliable packing solutions to ensure all equipment reaches your mill in perfect condition. Each component is securely packaged using standard export wooden cases, steel frames, or moisture-proof wrapping as required.

Our logistics team arranges timely delivery by sea, land, or air according to customer needs. We work with trusted international freight forwarders to guarantee smooth shipping, accurate documentation, and on-time arrival.

Prev: Toilet paper rewinder

Paper Machine Manufacturer & Supplier | Complete Paper Mill Solutions

Paper Machine Manufacturer & Supplier | Complete Paper Mill Solutions