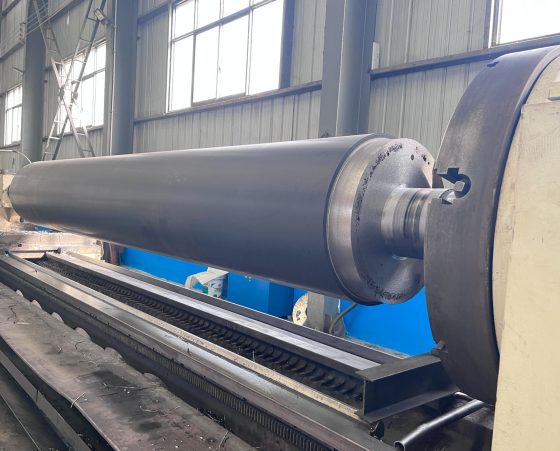

Press Roll for Paper Machine – High-Performance Dewatering & Nip Stability

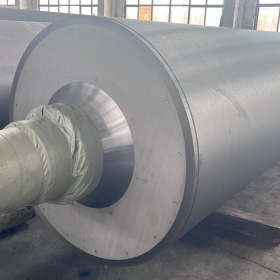

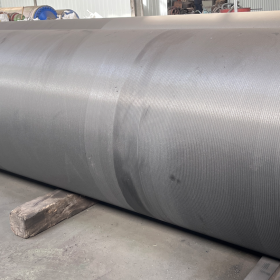

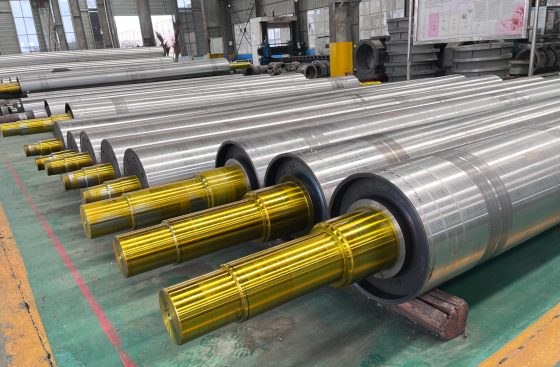

Our пресс-рулон is engineered for efficient dewatering, stable nip pressure, and long-term durability in the press section of the paper machine. Manufactured with high-precision machining and advanced dynamic balancing, our press rolls ensure uniform load distribution and improved sheet dryness, helping paper mills reduce steam consumption and increase production efficiency.

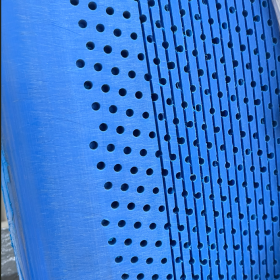

We supply a full range of press rolls, включая stone roll, rubber-covered press roll, suction press roll, double-felt press roll, grooved press roll, and custom-made designs for different paper grades and machine speeds.

Ключевые особенности

- High-precision machining ensures perfect concentricity and stable nip pressure.

- Optimized dewatering performance for higher outlet dryness and reduced energy cost.

- Premium roll shell materials available in alloy steel, cast iron, stainless steel, and composite structures.

- Optional rubber or PU covering with customized hardness, толщина, and surface patterns.

- Advanced dynamic balancing for high-speed operation and vibration-free performance.

- Excellent corrosion and wear resistance for long service life in heavy-duty operation.

Available Types

- Suction press roll

- Rubber covered press roll

- Stone roll / granite roll

- Grooved press roll

- Smooth press roll

- Double-felt and triple-felt press rolls

- Custom OEM rolls for Voith, Обучение, Andritz, Kadant and Chinese paper machines

Приложения

Suitable for all paper & board machines:

- Kraft paper / liner & fluting

- Tissue & towel paper

- Duplex board & white top

- Writing & printing paper

- Specialty paper production

Why Choose Our Press Roll?

With decades of experience in papermaking machinery manufacturing, we use advanced CNC equipment, precision grinding, and strict quality control to ensure each press roll meets international standards. Our rolls deliver higher dryness, reduced downtime, and optimal performance throughout the press section.

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики