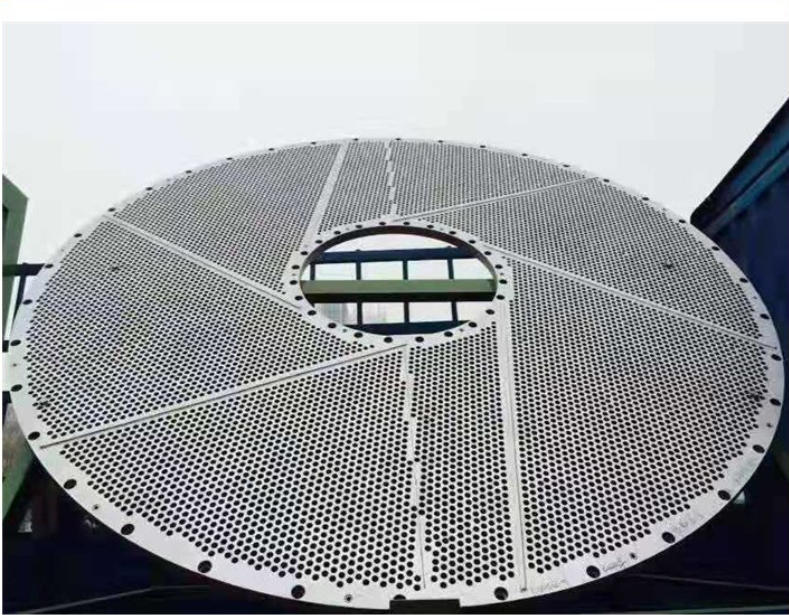

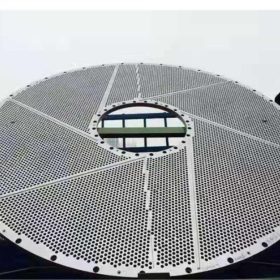

Протирающее сито / Pulper Screen Plate for Paper Recycling & Подготовка запасов

Our pulper sieve (also known as pulper screen plate or sieve plate for hydrapulper) is designed for high-efficiency fiber separation and contaminant removal in stock preparation systems. Manufactured from high-strength stainless steel and processed with CNC precision machining, our sieve plates ensure excellent durability, стабильная производительность, and long service life in demanding paper recycling environments.

Suitable for hydrapulpers, drum pulpers, D-type pulpers, and vertical pulpers, our sieves offer optimized hole geometry for superior fiber recovery and high throughput.

Ключевые особенности

- Premium stainless steel (SS304 / SS316 / Duplex Steel) for excellent wear resistance and corrosion protection.

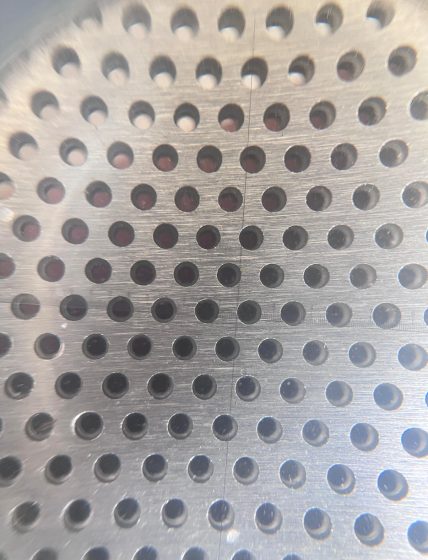

- Precision-drilled or CNC-milled hole patterns ensuring high fiber recovery and consistent pulp quality.

- Optimized open area improving productivity and reducing pulping energy consumption.

- Customizable hole size, slot width, and pattern to match different raw materials (OCC, ONP, SOP, MOW, mixed waste, etc.).

- Strong structure and heat-treated design for long service life with minimal maintenance.

Available Types

- Hole-type sieve plate

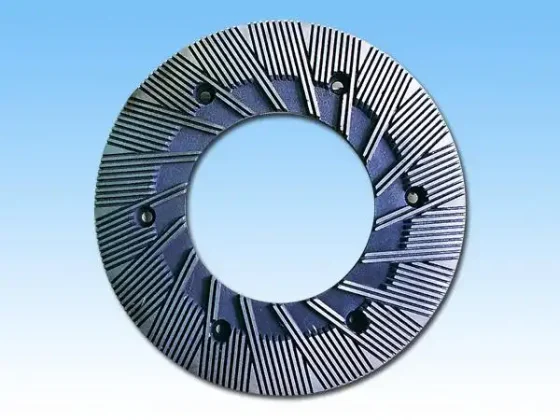

- Slot-type sieve plate

- Cone-shaped & stepped hole designs

- Flat, curve, or segment structure

Приложения

- OCC pulping

- Mixed waste paper pulping

- Deinking & recycling lines

- Tissue, kraft, дуплексная плата, and packaging paper stock preparation

- Гидропульпер, drum pulper, D-type pulper, vertical pulper

Why Choose Our Pulper Sieve?

With decades of experience in papermaking machinery and spare parts, we supply high-performance sieve plates built to improve pulping efficiency, reduce power consumption, and extend equipment lifetime. Each sieve is manufactured under strict quality control to guarantee accurate dimensions and seamless installation.

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики