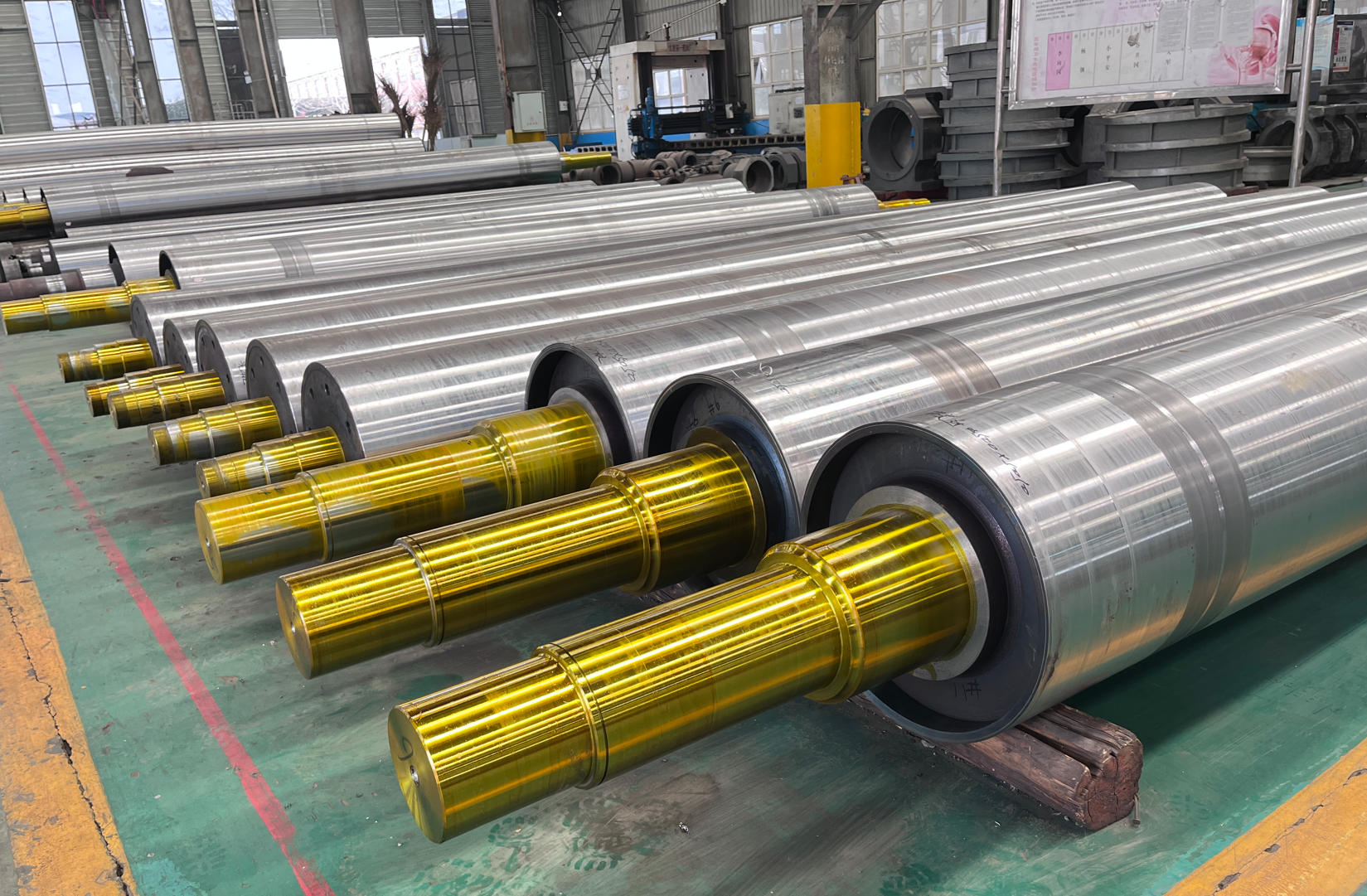

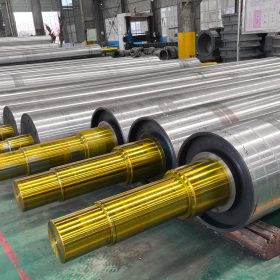

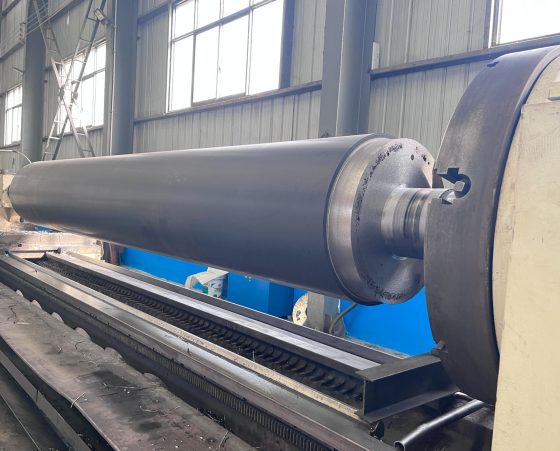

Guide Roll for Paper Machine – High-Precision Turning & Guiding Roller

Our guide roll (also known as paper machine guide roller) is designed to provide smooth web guiding, stable rotation, and long-term durability for all sections of the paper and board machine. Made from high-strength stainless steel or carbon steel with precision balancing, our guide rolls ensure low vibration, excellent runability, and consistent paper quality even under high-speed operating conditions.

Ключевые особенности

- High-strength stainless steel or carbon steel structure for excellent mechanical stability.

- Precision dynamic balancing (up to G1.6) ensuring smooth, vibration-free operation.

- Corrosion-resistant surface treatment suitable for humid and high-temperature environments.

- Lightweight, optimized design reduces energy consumption and improves machine efficiency.

- High-quality bearings and housings for extended service life and reliable performance.

- Available in customized diameters, face lengths, journal ends, and mounting structures.

Приложения

- Forming section guide roll

- Press section guide roll

- Dryer section turning roll

- Calendar & finishing section guide roll

- Rewinder & converting line guiding system

Advantages of Our Guide Roll

With professional manufacturing capability in papermaking rollers, we produce guide rolls using CNC machining, advanced welding, heat treatment, and precision grinding. Each roll undergoes dynamic balancing, pressure testing, and surface protection to ensure long service life and stable performance in high-speed paper machines.

Materials Available

- Stainless steel (SS304 / SS316)

- Carbon steel with chrome plating

- Aluminum alloy (for lightweight applications)

- Rubber-coated guide rolls (optional)

Why Choose Our Guide Rolls?

We provide reliable, high-precision guide rollers designed to improve web stability, reduce downtime, and enhance overall machine operation. Custom sizes and OEM designs are available to match all types of paper machines and converting equipment.

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики

Производитель бумагоделательных машин & Поставщик | Комплексные решения для бумажной фабрики