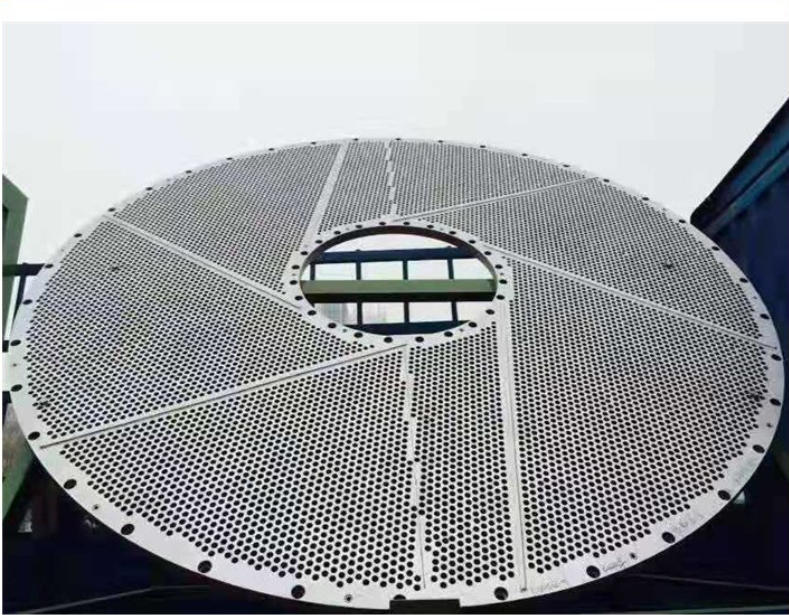

Pulper Sieve / Pulper Screen Plate for Paper Recycling & การเตรียมสต็อก

ของเรา pulper sieve (ยังเป็นที่รู้จักกันในนาม pulper screen plate หรือ sieve plate for hydrapulper) is designed for high-efficiency fiber separation and contaminant removal in stock preparation systems. Manufactured from high-strength stainless steel and processed with CNC precision machining, our sieve plates ensure excellent durability, ประสิทธิภาพที่มั่นคง, and long service life in demanding paper recycling environments.

Suitable for hydrapulpers, drum pulpers, D-type pulpers, and vertical pulpers, our sieves offer optimized hole geometry for superior fiber recovery and high throughput.

คุณสมบัติที่สำคัญ

- Premium stainless steel (SS304 / SS316 / Duplex Steel) for excellent wear resistance and corrosion protection.

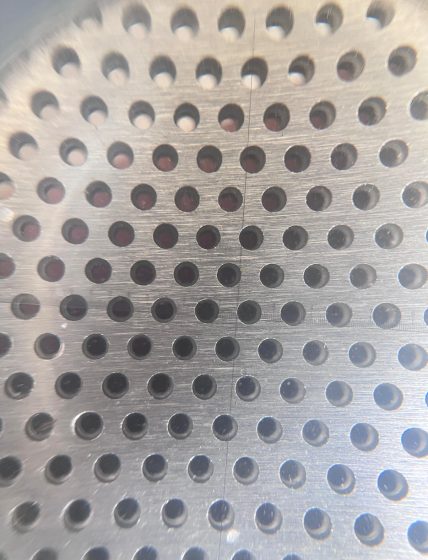

- Precision-drilled or CNC-milled hole patterns ensuring high fiber recovery and consistent pulp quality.

- Optimized open area improving productivity and reducing pulping energy consumption.

- Customizable hole size, slot width, and pattern to match different raw materials (OCC, ONP, SOP, MOW, mixed waste, etc.).

- Strong structure and heat-treated design for long service life with minimal maintenance.

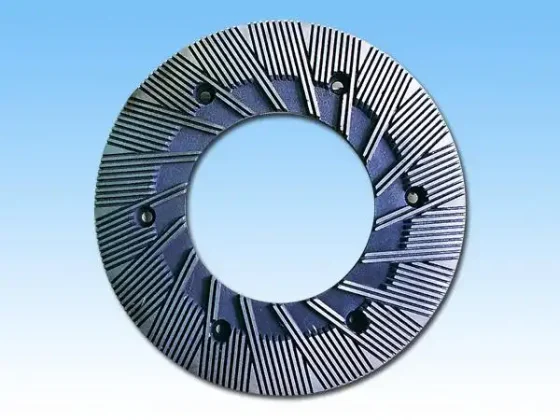

Available Types

- Hole-type sieve plate

- Slot-type sieve plate

- Cone-shaped & stepped hole designs

- Flat, curve, or segment structure

การใช้งาน

- OCC pulping

- Mixed waste paper pulping

- Deinking & recycling lines

- Tissue, kraft, บอร์ดดูเพล็กซ์, and packaging paper stock preparation

- Hydrapulper, drum pulper, D-type pulper, vertical pulper

Why Choose Our Pulper Sieve?

With decades of experience in papermaking machinery and spare parts, we supply high-performance sieve plates built to improve pulping efficiency, reduce power consumption, and extend equipment lifetime. Each sieve is manufactured under strict quality control to guarantee accurate dimensions and seamless installation.

ผลิตเครื่องผลิตกระดาษ & ผู้จัดหา | โซลูชั่นโรงงานกระดาษแบบครบวงจร

ผลิตเครื่องผลิตกระดาษ & ผู้จัดหา | โซลูชั่นโรงงานกระดาษแบบครบวงจร