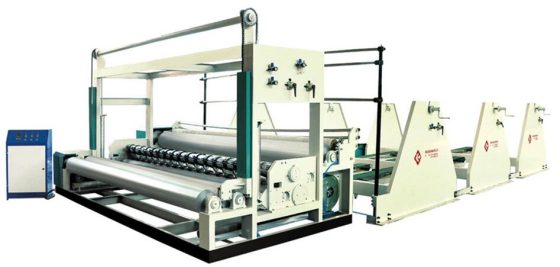

Full-automatic tissue paper rewinding/perforation/embossing machine

The full-automatic tissue paper rewinding/perforation/embossing machine is mainly used for rewinding the tissue jumbo roll into two-layer or three-layer toilet paper. It adopts computer programming control of PLC and pneumatic control system, setting perforating, rolling, embossing, automatic gluing, cutting, sealing in one machine, automatically running, simply operating. It can produce hollow -core and solid-core toilet roll. The embossing device is optional, and the embossing pattern can be customized.

Specification:

| Type |

1575 |

1880 |

2400 |

| Parent roll size(มม) |

800*1750 |

800*2100 |

800*2600 |

| Diameter of production(มม) |

80-150 |

80-150 |

80-150 |

| Diameter of paper core(มม) |

30-50 |

30-50 |

30-50 |

| Speed (ม/ของฉัน) |

150-250ม/ของฉัน |

| Power |

3kw |

5.5kw |

7.5 |

| Dimension(มม) |

5600*2400*1500 |

5600*2700*1500 |

5600*3200*1500 |

High speed type:

| Type |

3200มม |

| Size of parent roll |

Φ1100×3000mm |

| Diameter of production |

Φ60-Φ150mm |

| Parent roll stands |

3 |

| Core inner diameter |

76มม |

| Perforating unit |

1 |

| Embossing unit |

1 |

| Speed |

300ม/ของฉัน |

| ความจุ |

6-7 tons |

| Pneumatic parent roll loading |

ใช่ |

| Rewinding for a given diameter function |

ใช่ |

| Automatic cutting& gluing& formation of a tail |

ใช่ |

| Control |

Frequency convertor& PLC |

| Power |

11 kw |

| Contour dimension |

6000×4000×1500mm |

| Weight |

4.5 tons |

ไตรมาสที่ 1: คุณเป็นผู้ผลิตหรือบริษัทการค้า?

ก: เราเป็นผู้ผลิตเยื่อกระดาษอย่างมืออาชีพ & เครื่องจักรโรงกระดาษที่มีดีไซน์ครบครัน, การผลิต, การติดตั้ง, และความสามารถหลังการขาย.

ไตรมาสที่ 2: คุณจัดหาเครื่องจักรผลิตกระดาษประเภทใด?

ก: เรามีสายการผลิตและอุปกรณ์สำคัญสำหรับกระดาษคราฟท์ครบวงจร, กระดาษทิชชู่, กระดาษวัฒนธรรม, บอร์ดดูเพล็กซ์, กระดาษพิเศษ, และอีกมากมาย.

ไตรมาสที่ 3: ระยะเวลาในการจัดส่งของคุณคือเท่าไร?

ก: โดยปกติ 60–120 วัน ขึ้นอยู่กับประเภทเครื่อง, กำลังการผลิต, และข้อกำหนดในการปรับแต่ง.

ไตรมาสที่ 4: ระยะเวลาการรับประกันของคุณคืออะไร?

ก: เรามีการรับประกัน 12 เดือนหลังจากการว่าจ้าง. มีการสนับสนุนทางเทคนิคตลอดอายุการใช้งาน.

คำถามที่ 5: คุณให้บริการติดตั้งและฝึกอบรม?

ก: ใช่. เราส่งวิศวกรมืออาชีพไปที่โรงงานของลูกค้าเพื่อทำการติดตั้ง, การว่าจ้าง, และการฝึกอบรมผู้ปฏิบัติงาน.

คำถามที่ 6: คุณจะแพ็คอุปกรณ์เพื่อการขนส่งอย่างไร?

ก: ทุกชิ้นส่วนบรรจุด้วยกล่องไม้มาตรฐานส่งออก, โครงเหล็ก, หรือการห่อแบบกันความชื้นเพื่อการขนส่งที่ปลอดภัย.

คำถามที่ 7: เงื่อนไขการชำระเงินของคุณคืออะไร?

ก: โดยทั่วไป 30% ชำระเงินล่วงหน้าและ 70% ก่อนจัดส่ง, หรือ L/C ที่เห็น. สามารถเจรจาเงื่อนไขอื่น ๆ ได้.

เราจัดให้ปลอดภัย, มืออาชีพ, และโซลูชั่นการบรรจุที่เชื่อถือได้เพื่อให้แน่ใจว่าอุปกรณ์ทั้งหมดส่งถึงโรงงานของคุณในสภาพที่สมบูรณ์. แต่ละส่วนประกอบได้รับการบรรจุอย่างปลอดภัยโดยใช้กล่องไม้ส่งออกมาตรฐาน, โครงเหล็ก, หรือห่อกันความชื้นได้ตามต้องการ.

ทีมงานโลจิสติกส์ของเราจัดเตรียมการจัดส่งทางทะเลให้ตรงเวลา, ที่ดิน, หรืออากาศตามความต้องการของลูกค้า. เราทำงานร่วมกับผู้ส่งสินค้าระหว่างประเทศที่เชื่อถือได้เพื่อรับประกันการจัดส่งที่ราบรื่น, เอกสารที่ถูกต้อง, และมาถึงตรงเวลา.

ผลิตเครื่องผลิตกระดาษ & ผู้จัดหา | โซลูชั่นโรงงานกระดาษแบบครบวงจร

ผลิตเครื่องผลิตกระดาษ & ผู้จัดหา | โซลูชั่นโรงงานกระดาษแบบครบวงจร