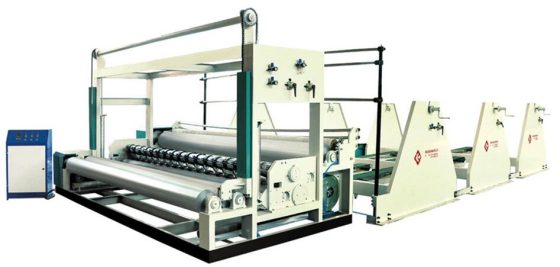

This machine is used for processing the bobbin paper into folded facial tissue. Put the folded facial tissue into the box, then it will become the final product-extracted and boxed type facial tissues. When you use it, you just need to pick out the tissue one after another. Easy and convenient! This machine adopts the installations of vacuum adsorption, automatic counting. Fast and accurate are its advantages. It is a first-class equipment in the area of facial tissue making machine.

Specification:

| Modèle |

JX-2L |

JX-3L |

| Product Size(mm) |

200×200(Other size are available) |

| Parent roll size (mm) |

1100*450 |

1100*640 |

| Speed |

500~800pcs*2/min |

500~800pcs*3/min |

| Embossing Device |

Steel to steel edge embossing |

| Power( kw) |

7.5 (Vacuum System)+3 |

| Controller |

Electromagnetic speed controlled |

| Dimensions(mm) |

5150x1300x1920mm |

5150x1400x1920mm |

T1: Êtes-vous un fabricant ou une société commerciale?

UN: Nous sommes un fabricant professionnel de pâte & machines de papeterie avec conception complète, production, installation, et capacités après-vente.

T2: Quels types de machines à papier fournissez-vous?

UN: Nous fournissons des lignes de production complètes et des équipements clés pour le papier kraft, papier de soie, papier culturel, carte recto-verso, papier spécial, et plus.

T3: Quelle est la durée de votre délai de livraison?

UN: Normalement 60 à 120 jours selon le type de machine, capacité de production, et exigences de personnalisation.

T4: Quelle est votre période de garantie?

UN: Nous offrons une garantie de 12 mois après la mise en service. Un support technique à vie est disponible.

Q5: Fournissez-vous l'installation et la formation?

UN: Oui. Nous envoyons des ingénieurs professionnels à l'usine du client pour l'installation, mise en service, et formation des opérateurs.

Q6: Comment emballer l'équipement pour l'expédition?

UN: Toutes les pièces sont emballées dans des caisses en bois conformes aux normes d'exportation, cadres en acier, ou un emballage résistant à l'humidité pour assurer un transport en toute sécurité.

Q7: Quel est votre délai de paiement?

UN: Typiquement 30% paiement anticipé et 70% avant expédition, ou L/C à vue. D'autres conditions peuvent être négociées.

Nous fournissons en toute sécurité, professionnel, et des solutions d'emballage fiables pour garantir que tous les équipements arrivent à votre usine en parfait état. Chaque composant est emballé en toute sécurité dans des caisses en bois standard d'exportation, cadres en acier, ou un emballage résistant à l'humidité selon les besoins.

Notre équipe logistique organise la livraison dans les délais par voie maritime, atterrir, ou air selon les besoins du client. Nous travaillons avec des transitaires internationaux de confiance pour garantir une expédition fluide., une documentation précise, et arrivée à l'heure.

Fabricant de machines à papier & Fournisseur | Solutions complètes pour usines de papier

Fabricant de machines à papier & Fournisseur | Solutions complètes pour usines de papier